Eagle Abrasives

Magic Sanding Disc

Magic Sanding Disc

SNS Auto Supply

750 11th Ave NE

West Fargo ND 58078

United States

Made in Japan

Choose options

Made in Japan

Made in Japan

A Diamond Abrasive Grain Disc

Experience the next level of sanding performance with our revolutionary 6" Magic Disc, meticulously crafted to meet the demands of professionals and enthusiasts alike. Engineered with premium diamond abrasive grains, this disc effortlessly tackles even the toughest OEM E-Coats, ensuring impeccable results with every pass. But the magic doesn't stop there – our advanced manufacturing process ensures precise grain placement for a remarkably uniform finish, elevating the quality of your work to new heights.

Features:

🌟 Premium Diamond Abrasive Grains: Our Magic Disc is equipped with premium diamond abrasive grains that effortlessly sand through the hardest and toughest OEM E-Coats, ensuring exceptional results every time.

🚗 Efficient and Cost-Effective: With its advanced manufacturing process, a single disc can complete ED sanding for multiple vehicles, making it a cost-effective solution for your sanding needs.

🔍 Precise Grain Placement: The advanced manufacturing process ensures more precise grain placement, resulting in a more uniform finish on your surfaces.

🔄 Hook & Loop Backing: The Hook & Loop backing design allows for convenient disc replacement, cooler sanding, and clog-free dry sanding, enhancing your overall sanding experience.

🕳️ Pre-Punched Holes: Featuring 15 pre-punched holes, our Magic Disc offers increased compatibility with a variety of back-up pads and dustless vacuum systems, maximizing efficiency and dust extraction during sanding operations.

🏆 Manufactured by Kovax: With over 90 years of experience in coated abrasive technology, Kovax is a trusted leader in the automotive, metalworking, and woodworking industries, ensuring the highest quality and reliability in every Magic Disc.

Information:

Size(s): 6".

Content(s): 1 Box of 10 Discs.

Use Recommendations:

FAQs

Sandpaper Explained

Definition:

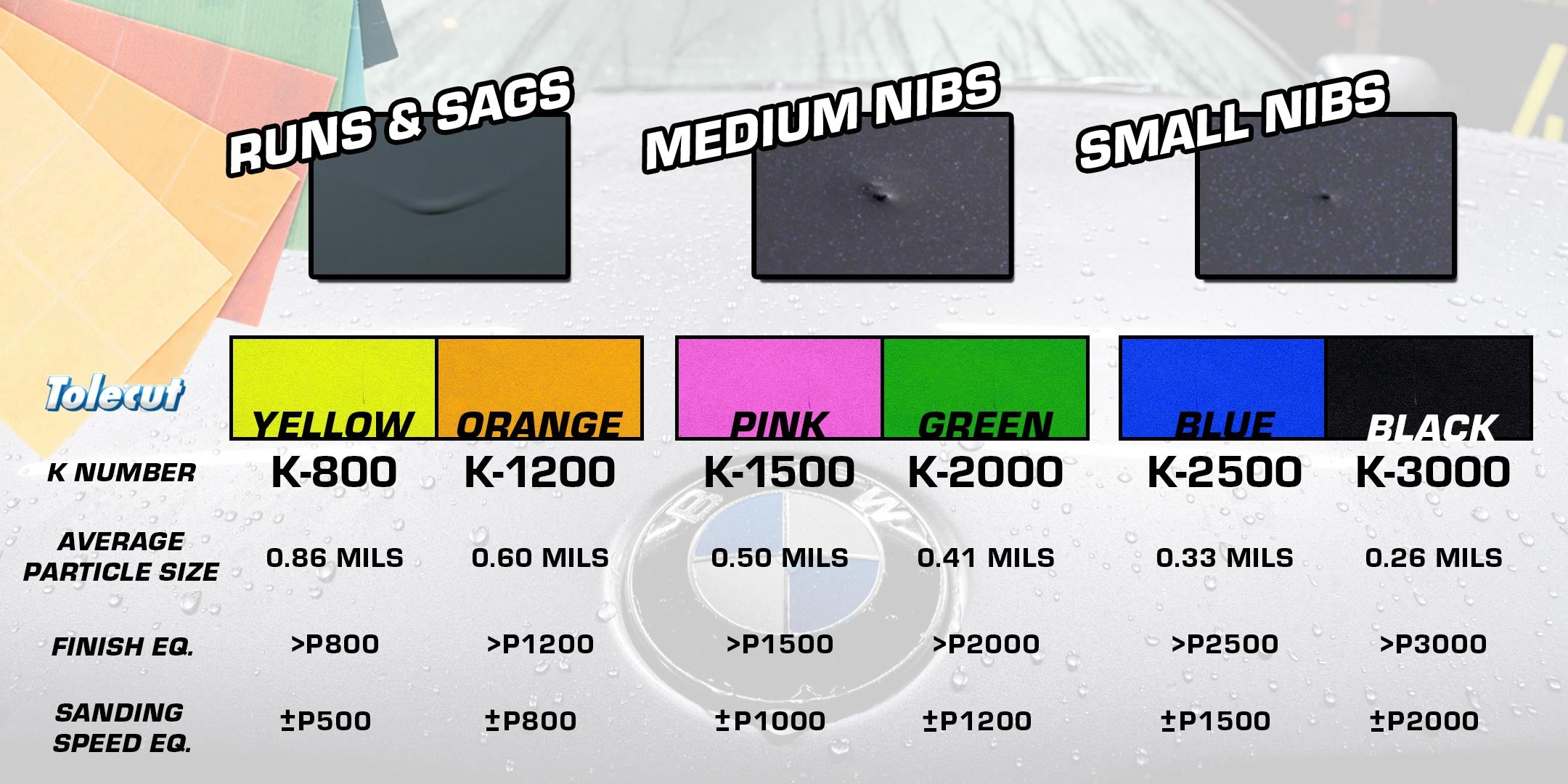

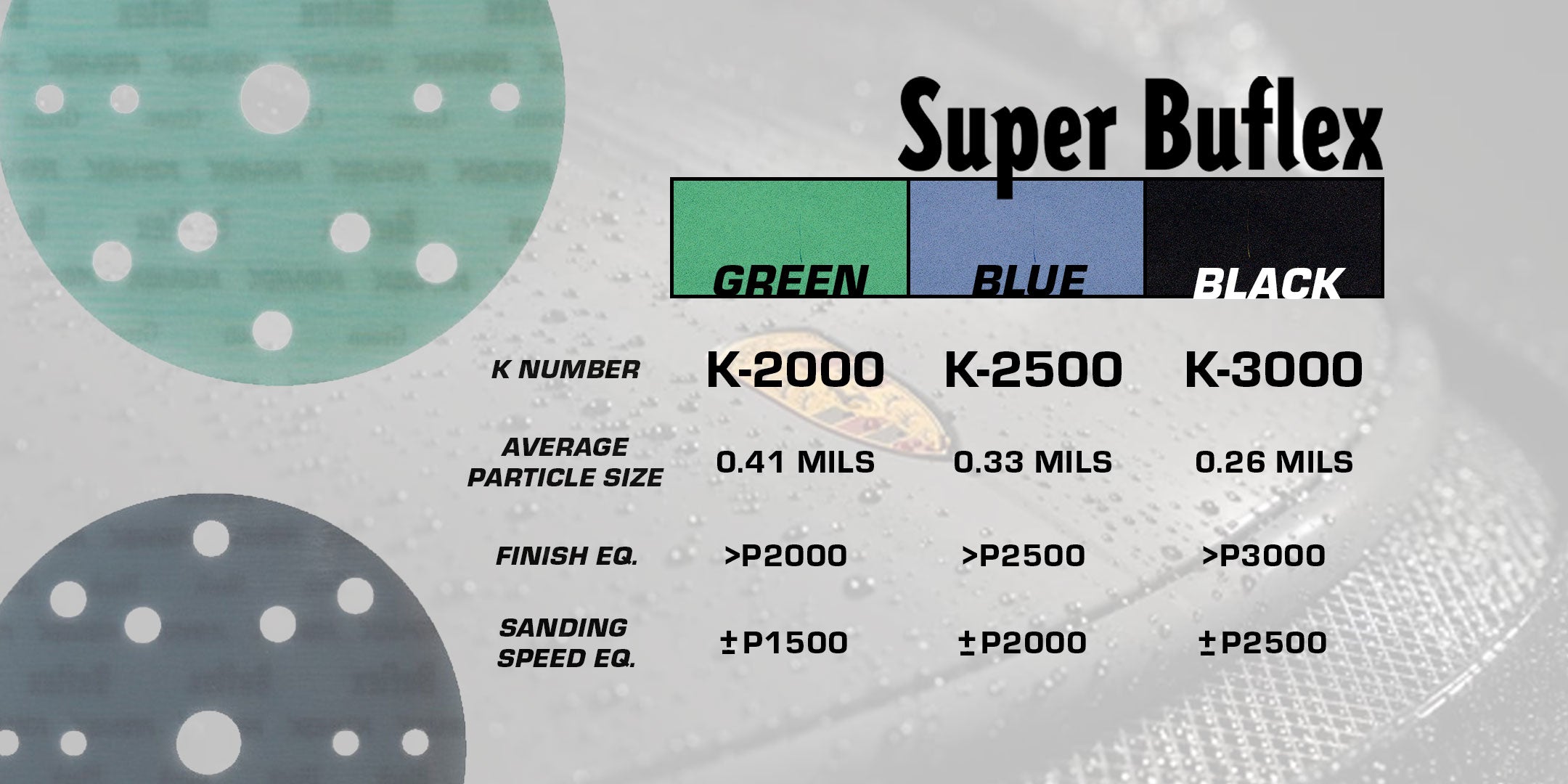

A K-number (like K-2000 or K-3000) is a grit rating used in the FEPA system (European standard for sandpaper and abrasives).

The number tells you how fine the abrasive particles are. Lower K-numbers (K-400, K-800) → bigger particles → rougher scratches → faster cutting. Higher K-numbers (K-2000, K-3000, K-5000) → smaller particles → finer scratches → smoother finish.

Example for Sanding Clear Coats:

- K-800 → good for knocking down orange peel but leaves visible sanding marks.

- K-2000 → much finer, starts blending scratches and haze.

- K-3000 → very smooth, leaves light marks that polish out easily.

Examples:

Think of it like pebbles on a beach.

- Low K-number = big pebbles

- High K-number = fine soft sand

When we talk about average particle size in sandpaper, we’re really describing the size of the abrasive grains that do the cutting. The number (in microns) represents the average size of those particles. For example, a K-2000 paper has particles around 10 microns, while a K-3000 has particles closer to 6 microns. The larger the particles, the deeper the scratches they leave in the clear coat; the smaller the particles, the shallower the scratches.

On a vehicle’s clear coat, this matters because each sanding step creates a pattern of scratches that need to be refined by the next step. If you begin with something like K-800 or K-1000, the scratches are deep and very visible. These grits cut fast, so they’re useful for knocking down heavy orange peel or severe defects, but they require a lot of refinement afterward. Moving into the K-1500 to K-2000 range, the scratches become finer and easier to polish away, but you’re still not ready to finish at that stage. Once you get to K-2500 and especially K-3000, the scratches are shallow enough that a polishing compound and pad can remove them completely, leaving a glossy surface.

The concept of particle size helps you understand why sanding is always a progression. You can’t jump straight from a coarse grit to polish, because the scratches are too deep for polish to remove efficiently. Instead, you reduce the scratch depth step by step until the final marks are so fine that polishing erases them. In practical terms, most detailers might start with K-1500 to level clear coat, refine with K-2000, and then finish with K-3000 before compounding. This gives a smooth transition where each stage cleans up the scratches from the last, without leaving anything too deep for polishing to handle.

Finish EQ or “Finish equivalence” in car sanding is a way of describing how smooth a surface looks and feels after being sanded with a certain grit, compared to what that same surface would look like if it had been finished with another grit. It’s basically a reference point. Since different sanding systems exist, the same number doesn’t always mean the same thing. For example, K-2000 and US 1000 don’t cut exactly the same, but the finish equivalence might be described in terms of what the paint surface resembles, it's like saying, “this looks like the finish you’d get from 1500 in one system” or “this sands like 2000 in another system.”

In car sanding, finish equivalence is important because what ultimately matters is not the grit number printed on the paper, but the scratch pattern it leaves in the clear coat. If you sand a panel with K-3000 film-backed paper, the surface might polish out like it had been sanded with something even finer (say a 4000–5000 grit foam disc). This is because film and foam abrasives distribute their particles more evenly, so their finish equivalence is “higher” than the raw grit number suggests. On the other hand, an 800-grit sheet of standard paper will leave a coarser finish than an 800-grit disc made with more uniform abrasives, even though the labeled grit is the same.

Sanding Speed EQ or “Sanding speed equivalence” in car sanding refers to how quickly a given abrasive removes material compared to another abrasive, while taking into account not just the grit number but also the backing type, abrasive coating, and pressure applied. In simpler terms, it’s a way of comparing how fast one sandpaper or sanding disc will cut versus another under similar conditions.

For example, a K-1500 film-backed abrasive might remove clear coat much faster than a traditional paper-backed K-1500 sheet because the film keeps the abrasive grains more evenly spaced and prevents them from loading up. Similarly, a foam-backed sanding pad might cut slower than a hard-backed disc, even if the grit number is the same, because the foam compresses and reduces the effective pressure on the surface.

Sanding speed equivalence is important in automotive detailing because it helps you predict how long a job will take and how many passes you need to level a panel. Coarser grits cut fast but leave deep scratches, while finer grits cut slower but leave a smoother finish. Understanding speed equivalence allows a detailer to balance cut rate versus finish quality, so you don’t overwork the clear coat or undercut it.

Essentially, it’s a practical measure of how aggressive an abrasive feels on paint, rather than just relying on grit numbers. High sanding speed equivalence means the abrasive removes material quickly; low speed equivalence means it’s slower and more controlled.

Sanding Clear Coat Simplified

In car detailing, mils and microns (µm) are just two different ways of measuring very thin layers. A mil is one-thousandth of an inch (0.001"), while a micron is one-millionth of a meter, and one mil equals about 25.4 microns.

1 mil = 25.4 (µm)

Automotive clear coat is usually around 40–50 microns thick (if you are lucky), or about 1.5–2.0 mils.

Sandpaper grit is also tied to microns, because the abrasive particles are measured by their size. For example, K-800 grit uses particles around 22 microns across, while K-3000 grit uses particles closer to 6 microns. The larger the particle, the deeper the scratch it leaves in the clear coat. Since sanding and polishing remove clear coat layer by layer, understanding mils and microns helps detailers know how much material they are removing, how aggressive their sanding is, and how close they are to the safe limits of the paint before risking a burn-through.

The FEPA system (Federation of European Producers of Abrasives) is the standard most commonly used in automotive finishing and detailing. It’s usually marked with the letter “P” or sometimes “K” in front of the grit number, such as P-2000 or K-2000. FEPA grits are defined by the average particle size in microns (µm), which makes them very consistent, especially at the higher grits used for wet sanding clear coat and preparing surfaces for polishing.

The ANSI system (American National Standards Institute), also known through CAMI (Coated Abrasives Manufacturers Institute), is the older U.S. standard. These grits are typically written as plain numbers, such as 400 grit or 600 grit, without a prefix. ANSI works well for coarser sandpapers, like those used in woodworking or construction, but it becomes less precise at finer levels. In fact, above 600 grit, ANSI grades become rare, and most manufacturers switch to FEPA standards instead.

This is where confusion often happens in car detailing. A sandpaper marked P-2000 in the FEPA system is not the same as “2000 grit” in the U.S. sense, in fact, ANSI doesn’t even officially go that high. A P-2000 paper is actually closer to an ANSI 1000 grit, with an average particle size of about 10 microns. Likewise, P-3000 paper works out to around ANSI 1200 grit, or about 6.5 microns.

In short, if you see a grit number with a P or K, it’s using the FEPA European scale. If it’s just a number in the U.S., it’s ANSI. Since the two systems don’t match up evenly, the best way to compare is by looking at the micron size which tells you the real scratch depth you’re putting into the clear coat.

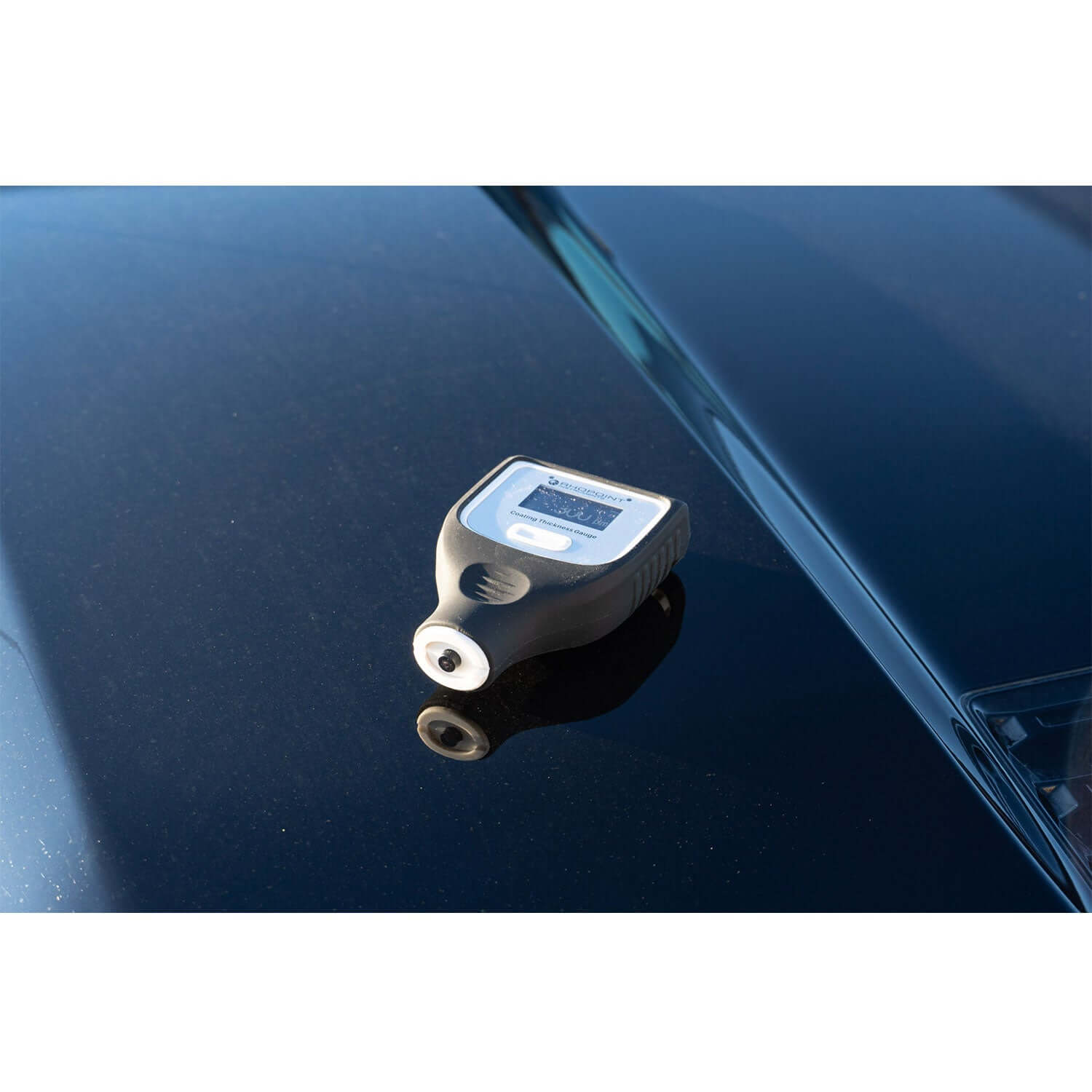

Forget the Guessing

Burnthrough Be-Gone

Rhopoint Americas

Rhopoint Coating Thickness Gauge

Rhopoint Coating Thickness Gauge

SNS Auto Supply

750 11th Ave NE

West Fargo ND 58078

United States