Rhopoint Americas

Rhopoint Detailometer Paint Correction Measuring Device

Rhopoint Detailometer Paint Correction Measuring Device

SNS Auto Supply

750 11th Ave NE

West Fargo ND 58078

United States

Made in USA

Choose options

Made in USA

Made in USA

The Ultimate Device for Clear Coat Enhancement

Stop leaving your results to subjective opinion. Prove your paint correction effectiveness with definitive, data-driven results using the Rhopoint Detailometer. This tool measures the key optical parameters of any automotive finish; Haze, Gloss, Reflected Image Quality (RIQ), Distinction of Image (DOI), and RSPEC. What value does this offer your detailing? You can now prove with irrefutable data that the paint correction is effective and narrow down exactly how effective it is. No more opinion based results, actual proven solutions with measureable data, leaving you 2 steps ahead of the competition offering the most luxurious paint correction. Show your customers exactly how their vehicle’s appearance has improved and build unshakeable trust with measurable proof. QUICK REPORT APP AVAILABLE ON THE APP STORE & GOOGLE PLAY STORE, See below for a link to download.

Why Choose the Detailometer?

📊 Subjectivity for Factual Data: Measure and prove the quality of your work. Capture “before” and “after” readings for Haze, Gloss, RIQ, DOI, and RSPEC to demonstrate your impact scientifically.

🎯 Measure What the Eye Sees: (Scroll Down for Full Explainations)

-

Haze: Quantifies scattered light from micro-scratches, swirls, and polishing marks. Lower number = clearer finish.

-

Gloss: Measures light reflection (in Gloss Units [GU]). Higher number = deeper, mirror-like shine.

-

RIQ (Reflected Image Quality): Evaluates orange peel and surface waviness. Higher number (0-100) = less distortion.

- DOI (Distinction of Image): A measure of how clearly a reflected image will appear in a reflective surface.

- RSPEC: Detects subtle texture and longer-wavelength imperfections. Higher number = smoother surface.

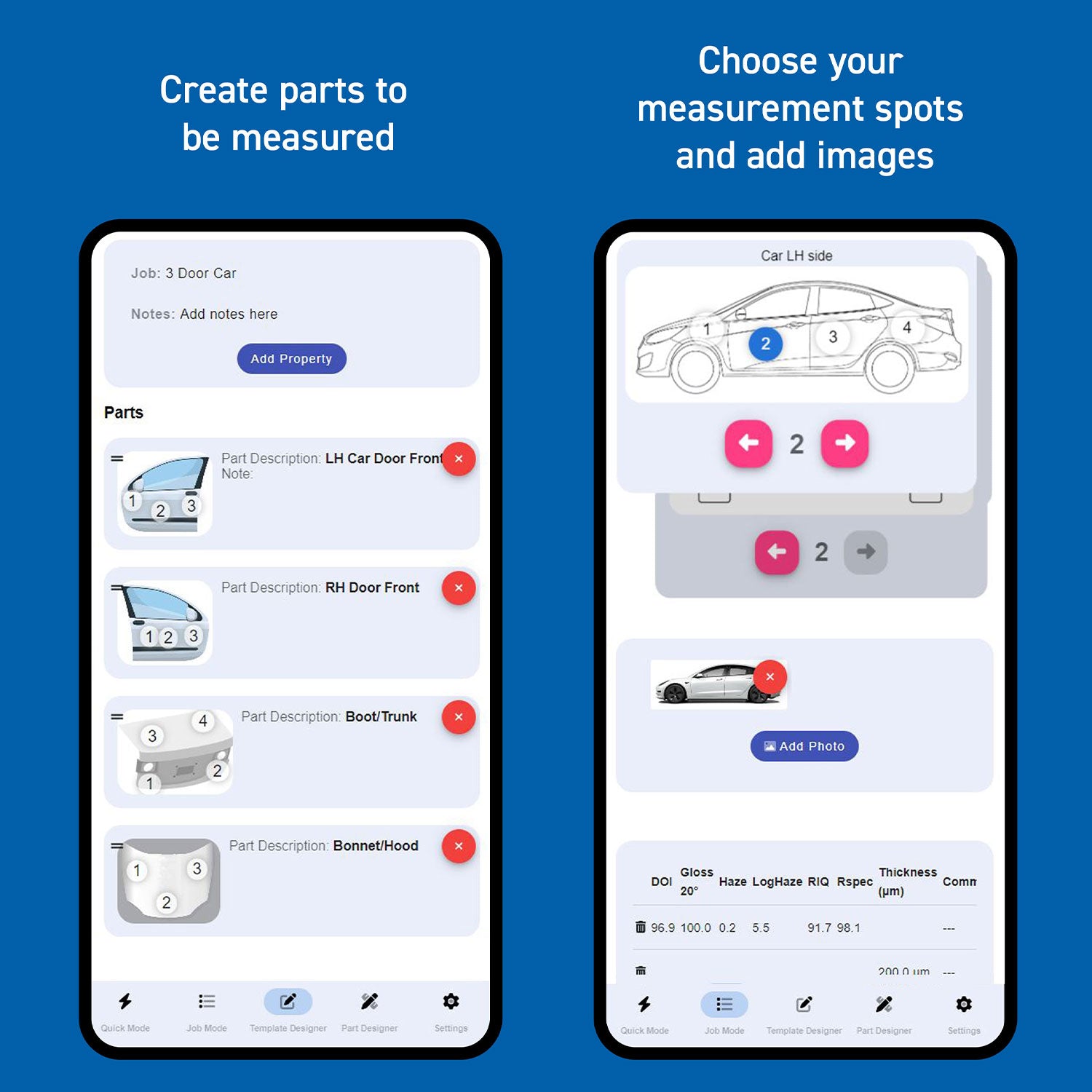

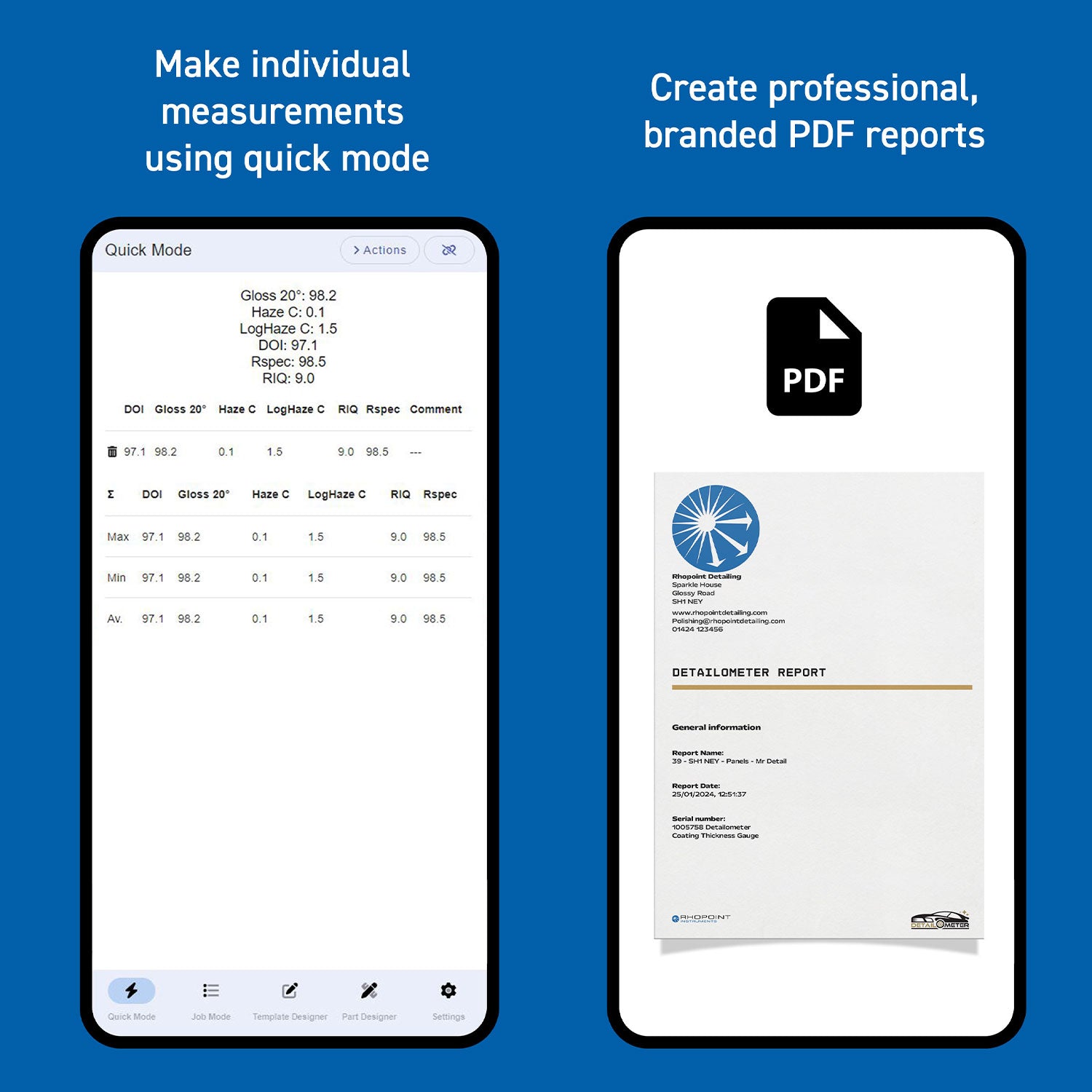

📱 Seamless App Integration (iOS/Android): Define measurement points, capture readings, and generate professional, printable reports instantly, all within a single, intuitive app.

🔍 Build Customer Trust & Value: Show, don’t just tell. Provide documented proof that you enhanced the finish without compromising clear coat integrity, enhancing your service from a detail to a certified correction.

⚙️ Professional-Grade Precision: Engineered for enthusiats or detailers who demand accuracy and credibility in every assessment.

Directions for USE:

Additional Information:

Functionality: Measuring Gloss & Quality of Clear Coat.

Power Source: USB Charger (Included)

Size: 6" x 2.5" x 4".

Content(s): 1 Detailometer Kit.

What to Use it for:

Manuals:

What is all of this?

Great question! Like you we were (and still are some days) very confused about what all the mils, microns, RIQ, etc. meant. So, we break it all down in the information below and we truly hope it will help your process evolve!

Coating Thickness Measuring

The measurement the tool uses takes place be signaling between the metal surface you are working on and the magnet that resides in the device, the resulting measurement it the thickness of the layers in-between.

Measurements are in micrometers "μm" (AKA Microns) which is an imperial (European) measurement form for 1/1,000,000 of a meter, the American equivalent would be mils measuring in at 1/1,000 of an inch.

1 μm = 25.4 mils

For example if you have 3 mils of thickness on a clear coat you would take 3x25.4 and get the American equivalent of 76.2.

**YOU CAN ALSO ADJUST YOUR RHOPOINT DEVICE TO READ IN EITHER ONE**

The industry standard for clear coat that is considered "too thin" for many beginners is roughly 3 mils or 80-100 microns.

We are suggesting to not do correction at these levels, but understand clear coat now-a-days are getting less and less thin so for your sake just please proceed with caution!

Detailometer FAQ

None of the Detailometer measurements directly measure clear coat thickness. The detailometer is a separate device from the coating thickness gauge and measures optical surface quality not thickness. What it measures;

- How light reflects from the top microns of the clear coat.

- The severity of micro-marring, haze, texture, and clarity loss.

- How well the clear coat surface has been leveled and refined.

Define GU:

Gloss 20° measures traditional gloss units (GU) for a vehicle. It measures these units using a reflection of light accross the surfaces finish. The light reflection is at an angle of 20° which is good for high-end finishes on automotive clear coat.

What is good and bad GU?

85–95 GU → Excellent

75–85 GU → Good

<75 GU → Dull or marred

How do I explain this value to my customer?

Gloss Units are a standard industry measurement for shine. The Higher gloss numbers indicate a deeper, more shiny finish.

Define Haze:

Haze measures how much light is being scattered by tiny scratches and imperfections in the clear coat instead of reflecting cleanly back like a mirror. When light scatters, the paint either looks cloudy or milky rather than sharp and crisp. A lower haze value means the clear coat surface is smoother and clearer, allowing light to reflect evenly because it is scattering less!

What causes haze?

- Micro-scratching

- Improper compounding

- Dual-Action haze

- Oxidation

- Poorly leveled clear coat

What is good and bad Haze?

<1.0 → Exceptional finish

1.0–2.5 → Very good corrected paint

2.5–5.0 → Visible haze

>5.0 → Poor finish / heavy marring

How do I explain this value to my customer?

Haze measures how much light is being scattered by tiny scratches in the clear coat. The lower the number, the clearer and more refined the paint surface is. Pretty much the same as our definition above.

What is logHaze?

logHaze is a logarithmic transformation of the haze value. Instead of measuring haze in a straight line (linear scale), logHaze spreads the lower end of the scale apart, making small but important differences much easier to detect and repeat.

logHaze Example:

Imagine two cars:

Paint Condition | Haze (Raw) | logHaze

After Compounding | 0.9 Haze | 2.1 logHaze

After Polishing | 0.4 Haze | 1.2 logHaze

To your eye: The finishing step made a huge visual improvement

In raw haze: The change looks small numerically (0.5)

In logHaze: The change is clearly and meaningfully represented.

Define DOI:

DOI stands for Distinctness of Image. Basically this measures the sharpness of reflected images. The sharper the lines, shapes, and edges the higher the DOI.

How to Read DOI Scale?

- 0–100

- Higher = better

What is good and bad DOI?

90–100 → Show-car / ceramic-ready

80–90 → High-quality correction

70–80 → Acceptable but not refined

<70 → Noticeable distortion

What Causes Low DOI?

- Orange peel

- Micro-marring

- Poor Clear-Coat leveling

- Texture left after Compounding

How do I explain this value to my customer?

DOI tells us how sharp reflections appear in the paint. Higher numbers mean the clear coat is smoother because it reflects images more clearly.

Define Rspec:

Rspec or Rspecific measures how efficiently the clear coat reflects light in a single, mirror-like direction. It evaluates how much light returns directly to the sensor at the exact reflection angle, rather than being scattered by surface texture or microscopic defects. Higher Rspec values indicate a smoother, more refined clear coat surfaces.

How to Read the Rspec Scale?

- Higher = Better

- 90–100 = Exceptional

- 80–89 = Very Good

- 70–79 = Good

- 60–69 = Fair

- <60 = Bad

What Rspec Indicates?

- Surface smoothness

- Resin leveling

- Polishing refinement

Relationship to Gloss: Similar to gloss but more angle-specific. Less influenced by color than traditional gloss units.

How do I explain this value to my customer?

Rspec tells us how much light the paint reflects straight back like a mirror. Higher numbers mean the surface is smoother and more refined. We use it to confirm the paint is truly polished, not just shiny.

Define RIQ:

RIQ (Reflected Image Quality) is often the best single metric for explaining results to customers because it mirrors human visual perception.

What Does RIQ Measure?

A composite index combining:

- DOI (Distinction of Image)

- Haze

- Surface texture effects

How to Read the RIQ Scale

- Higher = Better

- 95–100 = Exceptional

- 90–94 = Excellent

- 85–89 = Very Good

- 80-84 = Good

- 70-79 = Fair

- 60-69 = Bad

- <60 = Very Bad

Professional Rule of Thumb:

- Below 80 → Paint condition is visibly compromised

- 80–89 → Good to very good correction

- 90+ → Premium or show-level finish

How do I explain this value to my customer?

RIQ is an overall clarity score that combines reflection, sharpness, and haze into one number. It closely matches what the human eye sees.

The Ideal Finishing Numbers

DOI = High (92-98)

logHaze = Low (0.6-1.0)

Rspec = High (90-98)

Gloss20 = High (90-95)

Technical Meaning: The clear coat is smooth, refined, and minimally marred, producing sharp reflections and deep gloss.

High Gloss + High Haze

Gloss20 = High (88-94)

logHaze = High (1.8-2.6)

Rspec = Moderate to High (78-88)

Technical Meaning: Surface reflects light strongly but also scatters it. Micro-marring is present even though shine looks strong. This typical after aggressive compounding stage.

Low Gloss + Low Haze

Rspec = High (85-92)

logHaze = High (1.0-1.8)

DOI = Low (72-80)

Technical Meaning: There is minimal micro-scratching, but the clear coat lacks resin smoothness (worn clear coat) or has oxidation, limiting reflectivity.

High Rspec + Low DOI

Rspec = Low (60-70)

logHaze = Low (0.8-1.3)

Gloss20 = Low (68-78)

Technical Meaning: The surface reflects light efficiently, but reflection sharpness is reduced by clear coat texture such as orange peel.

Moderate Haze + High DOI

Rspec = Moderate (75-85)

logHaze = Moderate (1.4-2.0)

DOI = High (88-94)

Technical Meaning: Reflections are sharp overall, but some micro-marring remains, common after single-step corrections. Indicates a 2-3 step correction is needed.

High Rspec + High Gloss + High Haze

Rspec = High (88-95)

logHaze = High (2.0-3.0)

Gloss20 = High (90-96)

Technical Meaning: The surface reflects strongly but also scatters light heavily, often due to fillers or oils masking defects.

High Gloss + Low Rspec

Rspec = Low (65-75)

DOI = High (78-85)

Gloss20 = High (88-92)

Technical Meaning: The paint appears shiny overall, but mirror-like reflection strength is limited, often due to soft clear coat or oils. They call this the Wide-Angle Shine.

For APPLE USERS

Quick Report App

Click the button below to access the app via your phone in order to gain access to the quick report system.

(App is free when you purchase a rhopoint device)

For Android Users

Quick Report App

Click the button below to access the app via your phone in order to gain access to the quick report system.

(App is free when you purchase a rhopoint device)